Details

Compressive Residual Stress

Product Summary

- Residual stress is important factor for fatigue strength of material, stress corrosion cracking and also Fretting fatigue.

- Toyo Seiko is available not only for the measurement of the residual stress but also submitting the best solution for the fatigue strength as a professional company of Shot Peening.

- In General, residual stress evaluation could work well for the solution against the deformation, crack which comes from heat treatment.

- Further the harmful tensile residual stress by heat treatment and machining could also be measured by X-ray diffractometer.

- Toyo Seiko would measure residual stress and retained austenite by X-ray diffractometer with the plenty of acknowledgement.

Machine Type

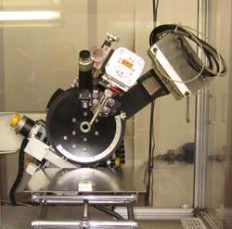

- Rigaku X-ray stress analyzer (PSPC, Auto MATE)

Fig 1 PSPC

Fig 2 AutoMATE

Measurement Service

- XRD (X-ray diffraction)

– Compressive residual stress inspection (2θ-sin2ψ method)

– Retained austenite inspection - Other inspection

– Hardness inspection

– Surface roughness inspection - Tube list and Measuring object material

– We have wide variety of tubes. Please see Table 1.

Table 1

Tube Measuring object material Cr steel, copper, brass, tin, nickel, carbide, chromium nitride, Ti-Ni shape memory alloy, aluminum oxide Cu zirconium oxide, α titanium V Magnesium, β titanium *We also have Cobalt (Co) tube.

- Collimator (radiated area) size

We have collimator listed in table 2.

Table2

4mm 2mm 1mm 0.5mm 0.3mm 0.15mm - XRD (X-ray diffraction)

Characteristics

- It is possible to measure a very small area by setting the beam diameter of the X-ray equipment to 150 μm.

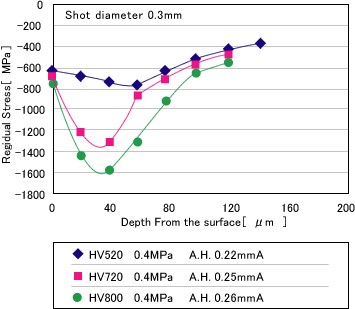

- It is important to understand the depth distribution in order to evaluate residual stress. We measure the residual stress distribution (up to a depth of about 3 mm) by electrolytic polishing. (* It may not be possible to measure depending on the measurement position and shape of the parts)

- In addition to steel materials, measurement of various alloys such as aluminum, nickel, titanium, zirconia, copper, carbide, TiNi shape memory alloy, etc. It is also possible to measure some ceramics.

- We also accept micro Vickers hardness (depth direction distribution) measurement (ASTM E384 compliant) and roughness measurement (JIS B0601:’01 compliant).

application

- In the case of using shot with a hardness of HV800 or more, the maximum compressive residual

stress value turns out to be approx 2 times larger compared with Shot of HV520 hardness.